Gridmesh Technical Specifications

About Gridmesh

What is it?

Gridmesh is manufactured from single sheet of low carbon steel that has been slit and expanded into a network of uniform shaped openings. As a result Gridmesh has a distinctive pattern that is both decorative and strong with a high strength to weight ratio. Gridmesh cannot unravel or fray and can be fabricated or formed to suit most requirements.

Manufacturing Detail

Gridmesh is wholly manufactured in New Zealand. Special drawing grade steel is refined here in New Zealand and the product is produced locally in Hamilton. As a result it is easy to manufacture within short lead times and to specific patterns, widths and materials. Standard finishes are unfinished black steel or galvanised. Upon request Aluminium can also be used within our manufacturing process for special applications. Manufacturing to special widths or lengths to meet your specific needs is also possible.

Benefits

Gridmesh has a non slip surface structure which assures complete safety to all users. It does not become slippery even in the worst of weather. It is also easily cleaned. It’s one piece construction and good deflection strength means it requires a very heavy blow to rupture. In security applications, it is impossible to make one or two cuts to make an opening making any penetration very time consuming thereby deterring any entry. It can be supplied in it’s natural raised state or flattened, in black steel, or galvanized and in many different patterns with each in different sizes and strands for every need.

Example Uses

Walkways, ramps, stair treads, work platforms, vehicle ramps, grating, flooring, stock crates, feed wagons, sheep races, woolshed flooring, piggeries, security, fencing, reinforcing. Lighter sheet thicknesses can be used for guarding and protections screens and decorative purposes.

Widths

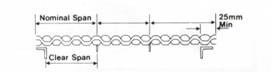

All widths quoted are nominal widths. For example, a 1200 quoted size could be between 1225mm and 1235mm depending on the mesh pattern. A 600 nominal size could be between 612mm and 615mm in size. Sheet sizes used in the construction of the mesh are initially 1228mm wide and 614mm wide. but often narrow slightly 1 to 2 mm during the formation process. Flattened products expand to about 1236mm and 618mm respectively.

Tolerances

All expanded mesh has some degree of curvature or camber along it length. This is caused through the alignment of the blades, trueness of the machinery, and how it’s been setup for that particular cut. On finer meshes a small error can multiply to a large degree of error over many cuts.

Our Gridmesh curvature tolerance guide is 5mm per metre along its length. This means that if you place a 1Metre straight edge against the edge of the mesh the tolerance allows for a 5mm variation from the straightedge along that length. Normally this is no problem to users and the degree of natural flex in the product allows for the mesh to be pushed into place relatively easily before being secured.

Our guides for stock lengths of mesh are for them to be not less than the nominal size but could be longer by up to a pitch plus the curvature tolerance.

Should closer or specific tolerances be nesessary, they can often be accomodated. Please discuss these when placing your order.

As with all all products, we reserve the right to alter sizing and tolerances as required.

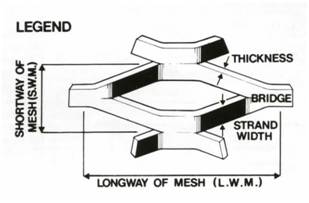

Terminology

The LWM (Long way mesh) is across the sheet while the SWL (Short way length) is along the length of the sheet. Thickness is the thickness of the sheet being used to cut the mesh from. The strand is the width of each slice.

Mesh Products

Agrimesh specification

| SWM | LWM | Strand | Thickness | Mass |

|---|---|---|---|---|

| 24.5mm | 75mm | 7.5mm | 3.0mm | 13.2Kg/SqM |

Agrimesh has a flattened surface finish. Often used in agricultural situations where the raised surface may not be appropriate for animals or product. Flooring in pens and on ramps, stock crates and feedout wagons are a common use. The mesh is a flattened form of walkway mesh.

Walkway specification

| SWM | LWM | Strand | Thickness | Mass |

|---|---|---|---|---|

| 24.5mm | 75mm | 7.5mm | 3.0mm | 13.2Kg/SqM |

Walkway mesh has a raised surface finish. It is the most commonly used product for access platforms. It has a non slip surface, and has good weight to strength ratio. We recommend that Walkway is always secured in position for maximum strength.

GR300 specification

| SWM | LWM | Strand | Thickness | Mass |

|---|---|---|---|---|

| 40mm | 135mm | 8.0mm | 5.0mm | 14.6Kg/SqM |

GR300 mesh has a raised surface finish. Its a heavier mesh than walkway but more open. Also used for flooring, it is common where a more open weave is desirable, especially around grain silos and processing equipment where the floor can otherwise be contaminated with product or waste or where higher strength storage floors are required.

GR400 specification

| SWM | LWM | Strand | Thickness | Mass |

|---|---|---|---|---|

| 44mm | 135mm | 11.0mm | 5.0mm | 19.5Kg/SqM |

GR400 mesh has a raised surface finish. A more open but heavier grade mesh than G300. It is often used where a stronger version of G300 is required. It’s common use is in and around grain silos and processing equipment where the floor can otherwise be contaminated with product or waste or higher strength storage areas.

GM450 specification

| SWM | LWM | Strand | Thickness | Mass |

|---|---|---|---|---|

| 24.5mm | 75mm | 7.5mm | 5.0mm | 22.0Kg/SqM |

GM450 mesh has a raised surface finish. This is quite a heavy grade mesh, but not quite a strong as GR400 but stronger than Walkway. It has the closer weave limiting items that can go through the weave. It’s use is primarily flooring and stair treads.

GM575 specification

| SWM | LWM | Strand | Thickness | Mass |

|---|---|---|---|---|

| 30mm | 75mm | 10.5mm | 5.0mm | 28.1Kg/SqM |

GM575 mesh has a raised surface finish. This is our heavy grade mesh. Aside from being strong, it is also a close weave. The extra cost of this mesh can often be offset by less required supporting structures.

GH1838 specification

| SWM | LWM | Strand | Thickness | Mass |

|---|---|---|---|---|

| 18mm | 38mm | 4.0mm | 3.0mm | 10.24Kg/m2 |

GH1838 has a raised surface finish. It is frequently used for fencing panels where difficulty in penetration is important. Slightly less dense than GH1638.

GK1851 specification

| SWM | LWM | Strand | Thickness | Mass |

|---|---|---|---|---|

| 18mm | 51mm | 4.5mm | 3.0mm | 11.9Kg/SqM |

GK1851 has a raised surface finish. It is frequently used for security purposes and fencing panels where difficulty in penetration is important. Slighly more open than the GK1638.

Gridmesh loading tables

All our engineering data is provided on a best endevours basis. The following tables are provided from the best information available to Cook and Galloway and have been derived over many years of use and tests and we endevour to ensure these are correct. Mesh however behaves in a different manner than sheet steel and very little complex structural analysis is readily available about it. Mesh loadings suitable for one mesh pattern may not be suitable for another, and different applications will have a different effect on the same products. Mesh will also behave in a different manner than sheet steel in both elasticity and available stretch. The application or use of these products based on this data remains the responsibilty of the user and not Cook and Galloway Engineers. We do advise that where there is any uncertainty, customers test the product in the application first.

The following information may also vary slightly from sample to sample within tolerances specified for sheet manufacture. Some of these variations can be caused through sheet material composition variations,slight strand variations and slight pitch variances even though each is within their respective tolerances.

Not all data is available. The tables will be further populated as additional data is gathered. If a figure is not available a hyphen is shown.

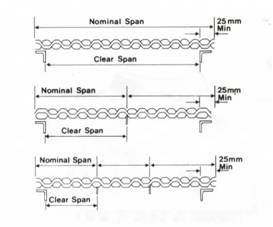

In the load tables below, the span deflection of 1/180th, 1/240th and 1/360th are quoted. These values are used as a guide because these are relative deflection points normally recommended for loading limits for mesh. 1/360th is a common acceptable loading for uniformly loaded mesh and 1/240 for a concentrated loading. The 1/240th and 1/180 is usable where some springeness underfoot is acceptable for uniformly distributed and concentrated loads respectively.

Generally loading for design is governed by deflections for simple spans and by load capacity for double and triple spans. We have provided both where available.

Maximum loads for no significant permanent deformation

Simple, double and triple span terminology

Maximum distributed load capacities in kPa for simple, double and triple spans

| Simple span | Simple span | Simple span | Double span | Double span | Double span | Triple span | Triple span | Triple span | |

| Span | 600mm | 900mm | 1200mm | 300mm | 450mm | 600mm | 200mm | 300mm | 400mm |

|---|---|---|---|---|---|---|---|---|---|

| Walkway | – | – | – | – | – | – | – | – | – |

| Agrimesh | – | – | – | – | – | – | – | – | – |

| GR300 | 4.80 | 2.20 | 1.20 | 19.60 | 8.90 | 5.10 | 43.00 | 21.00 | 11.00 |

| GR400 | 6.30 | 2.90 | 1.70 | 26.20 | 11.70 | 6.70 | 64.90 | 28.20 | 15.80 |

| GM450 | 5.70 | 2.60 | 1.50 | 23.40 | 10.50 | 6.00 | 50.40 | 24.90 | 14.30 |

| GM575 | 8.10 | 3.60 | 2.00 | 33.20 | 15.00 | 8.50 | 69.30 | 35.40 | 20.10 |

Table notes:

Loads for each mesh type are based on the following:

-

Spans are nominal spans based on typical sheet sizing

-

Load specified is the maximum load recommended to cause no significant perminant deformation.

-

Where perminant deformation can be tolerated a further 40% loading can be applied

-

Every 4th strand is secured 20-30mm in from the edge

-

Distributed loads are applied evenly over the clear area of the span

-

Unless otherwise specified, loads are in kiloPascals.

-

All loads are applied centrally in the open area of the mesh

Maximum concentrated load capacities in kN for simple, double and triple spans

| Simple span | Simple span | Simple span | Double span | Double span | Double span | Triple span | Triple span | Triple span | |

| Span | 600mm | 900mm | 1200mm | 300mm | 450mm | 600mm | 200mm | 300mm | 400mm |

|---|---|---|---|---|---|---|---|---|---|

| Walkway | – | – | – | – | – | – | – | – | – |

| Agrimesh | – | – | – | – | – | – | – | – | – |

| GR300 | 1.07 | 0.72 | 0.53 | 2.45 | 1.64 | 1.24 | 3.94 | 2.64 | 2.00 |

| GR400 | 1.41 | 0.94 | 0.70 | 3.23 | 2.18 | 1.65 | 4.98 | 3.49 | 2.67 |

| GM450 | 1.27 | 0.84 | 0.63 | 2.90 | 1.93 | 1.47 | 4.50 | 3.12 | 2.38 |

| GM575 | 1.79 | 1.20 | 0.90 | 4.12 | 2.76 | 2.08 | 6.28 | 4.49 | 3.38 |

Table notes:

Loads for each mesh type are based on the following:

-

Spans are nominal spans based on typical sheet sizing

-

Load specified is the maximum load recommended to cause no significant perminant deformation

-

Where perminant deformation can be tolerated a further 40% loading can be applied

-

Every 4th strand is secured 20-30mm in from the edge

-

Concentrated loads are applied over a diameter 100mm area

-

Unless otherwise specified, loads are in kiloNewtons.

-

All loads are applied centrally in the open area of the mesh

Simple span load deflection tables

Distributed loads in kPa to achieve given deflections %’s of a simple span

| Span | 600mm | 900mm | 1200mm | 600mm | 900mm | 1200mm | 600mm | 900mm | 1200mm |

|---|---|---|---|---|---|---|---|---|---|

| Span deflection % | 1/180th | 1/180th | 1/180th | 1/240th | 1/240th | 1/240th | 1/360th | 1/360th | 1/360th |

| Equiv deflection | 3.33mm | 5.00mm | 6.66mm | 2.5mm | 3.75mm | 5.00mm | 0.16mm | 2.50mm | 3.33mm |

| Walkway | – | – | – | – | – | – | – | – | – |

| Agrimesh | – | – | – | – | – | – | – | – | – |

| GR300 | – | – | – | 9.90 | 3.00 | 1.20 | 6.60 | 2.00 | 0.80 |

| GR400 | – | – | – | 18.30 | 5.50 | 2.20 | 12.30 | 3.70 | 1.50 |

| GM450 | – | – | – | 11.30 | 3.40 | 1.50 | 7.60 | 2.20 | 0.90 |

| GM575 | – | – | – | 18.30 | 5.50 | 2.40 | 12.30 | 3.70 | 1.50 |

Table notes:

Loads for each mesh type are based on the following:

-

Load specified is the load to achieve that deflection

-

Every 4th strand is secured 20-30mm in from the edge

-

Distributed loads are applied evenly over the clear area of the span

-

Unless otherwise specified, loads are in kiloPascals.

-

All loads are applied evenly over the open area of the mesh

Concentrated loads in kN to achieve given deflections %’s of a simple span

| Span | 600mm | 900mm | 1200mm | 600mm | 900mm | 1200mm | 600mm | 900mm | 1200mm |

|---|---|---|---|---|---|---|---|---|---|

| Span deflection % |

1/180th | 1/180th | 1/180th | 1/240th | 1/240th | 1/240th | 1/360th | 1/360th | 1/360th |

| Equiv deflection |

3.33mm | 5.00mm | 6.66mm | 2.5mm | 3.75mm | 5.00mm | 0.16mm | 2.50mm | 3.33mm |

| Walkway | – | – | – | – | – | – | – | – | – |

| Agrimesh | – | – | – | – | – | – | – | – | – |

| GR300 | 0.99 | 0.44 | 0.25 | 0.77 | 0.33 | 0.19 | – | – | – |

| GR400 | 1.82 | 0.82 | 0.47 | 1.37 | 0.62 | 0.35 | – | – | – |

| GM450 | 1.14 | 0.52 | 0.29 | 0.85 | 0.38 | 0.21 | – | – | – |

| GM575 | 1.84 | 0.83 | 0.46 | 1.37 | 0.62 | 0.35 | – | – | – |

Table notes:

Loads for each mesh type are based on the following:

-

Load specified is the load to achieve that deflection

-

Every 4th strand is secured 20-30mm in from the edge

-

Concentrated loads are applied over a diameter 100mm area

-

Unless otherwise specified, loads are in kiloNewtons.

-

All loads are applied centrally in the open area of the mesh

Double span load deflection tables

Distributed loads in kPa to achieve given deflections %’s of a double span

| Span | 300mm | 450mm | 600mm | 300mm | 450mm | 600mm | 300mm | 450mm | 600mm |

|---|---|---|---|---|---|---|---|---|---|

| Span deflection % | 1/180th | 1/180th | 1/180th | 1/240th | 1/240th | 1/240th | 1/360th | 1/360th | 1/360th |

| Equiv deflection | 1.66mm | 2.5mm | 3.33mm | 1.25mm | 1.88mm | 2.5mm | 0.83mm | 1.25mm | 1.66mm |

| Walkway | – | – | – | – | – | – | – | – | – |

| Agrimesh | – | – | – | – | – | – | – | – | – |

| GR300 | – | – | – | – | – | 12.50 | – | 19.40 | 8.40 |

| GR400 | – | – | – | – | – | 22.90 | – | – | 15.30 |

| GM450 | – | – | – | – | – | 14.10 | – | 20.20 | 9.70 |

| GM575 | – | – | – | – | – | – | – | 35.70 | 15.50 |

Table notes:

Loads for each mesh type are based on the following:

-

Load specified is the load to achieve that deflection

-

Every 4th strand is secured 20-30mm in from the edge

-

Distributed loads are applied evenly over the clear area of the span

-

Unless otherwise specified, loads are in kiloPascals.

-

All loads are applied evenly over the open area of the mesh

Concentrated loads in kN to achieve given deflections %’s of a double span

| Span | 300mm | 450mm | 600mm | 300mm | 450mm | 600mm | 300mm | 450mm | 600mm |

|---|---|---|---|---|---|---|---|---|---|

| Span deflection % | 1/180th | 1/180th | 1/180th | 1/240th | 1/240th | 1/240th | 1/360th | 1/360th | 1/360th |

| Equiv deflection | 1.66mm | 2.5mm | 3.33mm | 1.25mm | 1.88mm | 2.5mm | 0.83mm | 1.25mm | 1.66mm |

| Walkway | – | – | – | – | – | – | – | – | – |

| Agrimesh | – | – | – | – | – | – | – | – | – |

| GR300 | – | 2.40 | 1.38 | 4.01 | 1.82 | 1.02 | – | – | – |

| GR400 | – | – | 2.58 | – | 3.38 | 1.91 | – | – | – |

| GM450 | 6.19 | 2.76 | 1.60 | 4.63 | 2.06 | 1.19 | – | – | – |

| GM575 | – | 4.51 | 2.58 | 7.54 | 3.40 | 1.91 | – | – | – |

Table notes:

Loads for each mesh type are based on the following:

-

Load specified is the load to achieve that deflection

-

Every 4th strand is secured 20-30mm in from the edge

-

Concentrated loads are applied over a diameter 100mm area

-

Unless otherwise specified, loads are in kiloNewtons.

-

All loads are applied centrally in the open area of the mesh

Triple span load deflection tables

Distributed loads in kPa to achieve given deflections %’s of a triple span

| Span | 200mm | 300mm | 400mm | 200mm | 300mm | 400mm | 200mm | 300mm | 400mm |

|---|---|---|---|---|---|---|---|---|---|

| Span deflection % | 1/180th | 1/180th | 1/180th | 1/240th | 1/240th | 1/240th | 1/360th | 1/360th | 1/360th |

| Equiv deflection | 1.11mm | 1.66mm | 2.22mm | 0.83mm | 1.25mm | 1.66mm | 0.55mm | 0.83mm | 1.11mm |

| Walkway | – | – | – | – | – | – | – | – | – |

| Agrimesh | – | – | – | – | – | – | – | – | – |

| GR300 | – | – | – | – | – | – | – | – | 26.30 |

| GR400 | – | – | – | – | – | 73.10 | – | – | 49.20 |

| GM450 | – | – | – | – | – | – | – | – | 30.30 |

| GM575 | – | – | – | – | – | – | – | – | 49.20 |

Table notes:

Loads for each mesh type are based on the following:

-

Load specified is the load to achieve that deflection

-

Every 4th strand is secured 20-30mm in from the edge

-

Distributed loads are applied evenly over the clear area of the span

-

Unless otherwise specified, loads are in kiloPascals.

-

All loads are applied evenly over the open area of the mesh

Concentrated loads in kN to achieve given deflections %’s of a triple span

| Span | 200mm | 300mm | 400mm | 200mm | 300mm | 400mm | 200mm | 300mm | 400mm |

|---|---|---|---|---|---|---|---|---|---|

| Span deflection % | 1/180th | 1/180th | 1/180th | 1/240th | 1/240th | 1/240th | 1/360th | 1/360th | 1/360th |

| Equiv deflection | 1.11mm | 1.66mm | 2.22mm | 0.83mm | 1.25mm | 1.66mm | 0.55mm | 0.83mm | 1.11mm |

| Walkway | – | – | – | – | – | – | – | – | – |

| Agrimesh | – | – | – | – | – | – | – | – | – |

| GR300 | – | 4.98 | 2.89 | – | 3.80 | 2.18 | – | – | – |

| GR400 | – | – | 5.38 | – | 7.07 | 4.11 | – | – | – |

| GM450 | – | 5.87 | 3.38 | – | 4.43 | 2.53 | – | – | – |

| GM575 | – | 10.67 | 5.34 | – | 7.07 | 4.09 | – | – | – |

Table notes:

Loads for each mesh type are based on the following:

-

Load specified is the load to achieve that deflection

-

Every 4th strand is secured 20-30mm in from the edge

-

Concentrated loads are applied over a diameter 100mm area

-

Unless otherwise specified, loads are in kiloNewtons.

-

All loads are applied centrally in the open area of the mesh